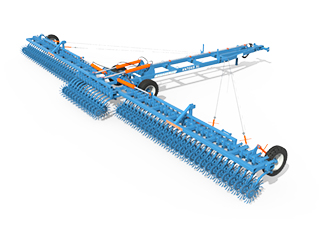

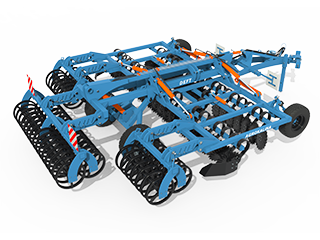

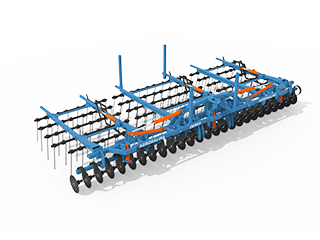

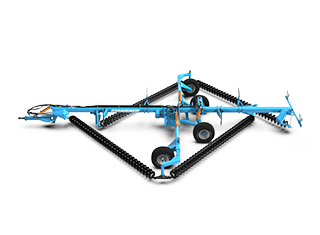

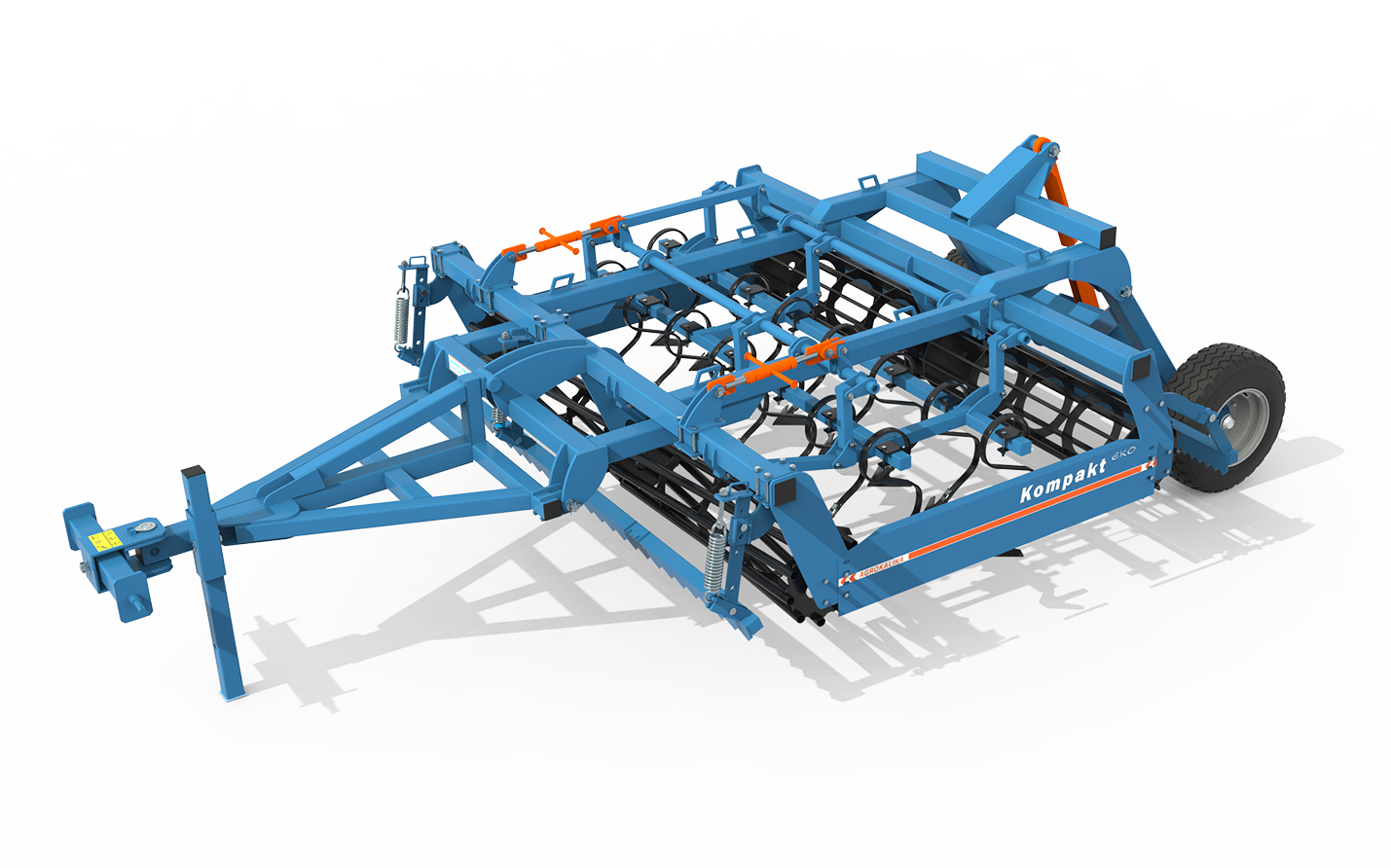

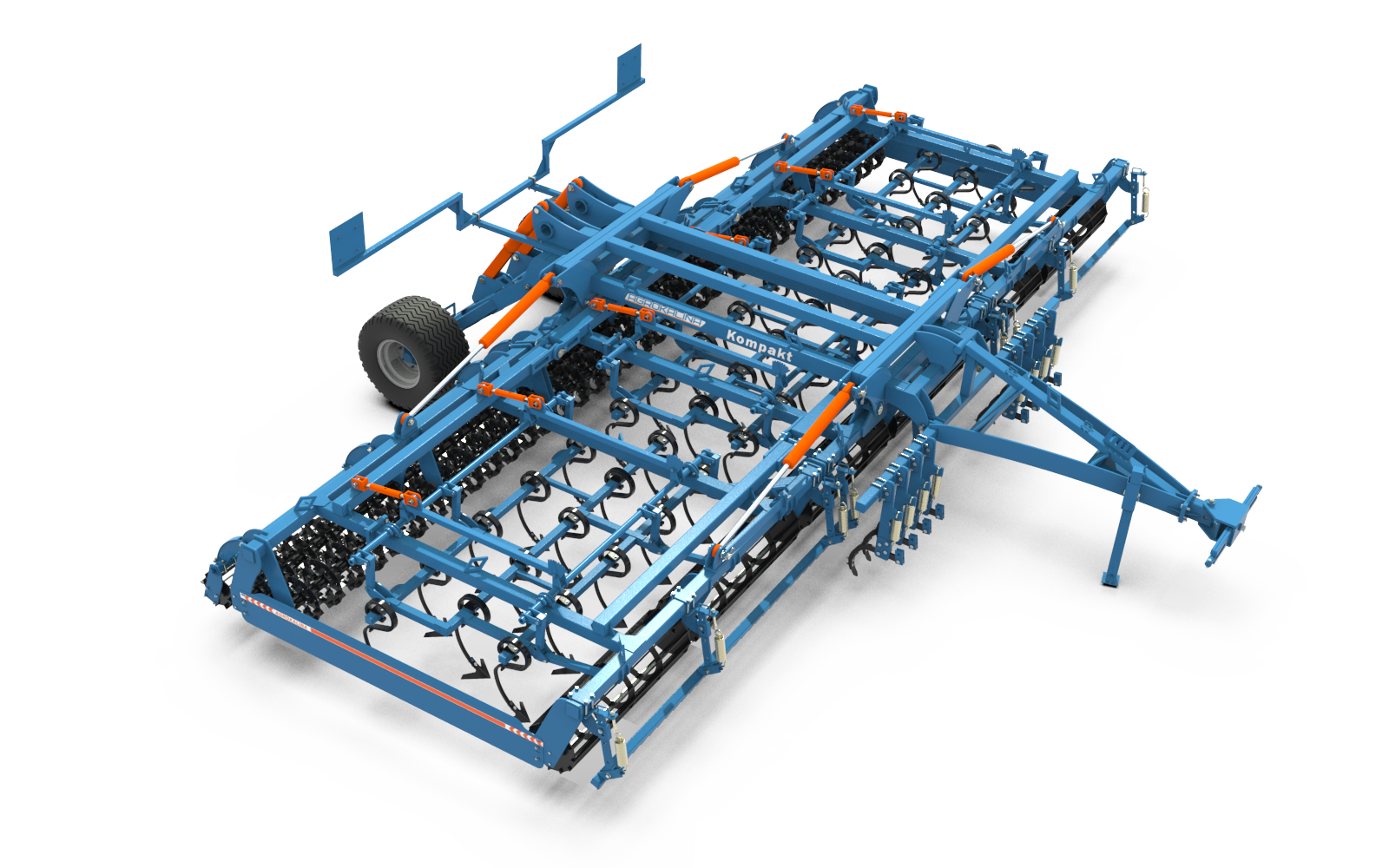

TRAILED CULTIVATOR (COMPACTOR) "Kompakt"

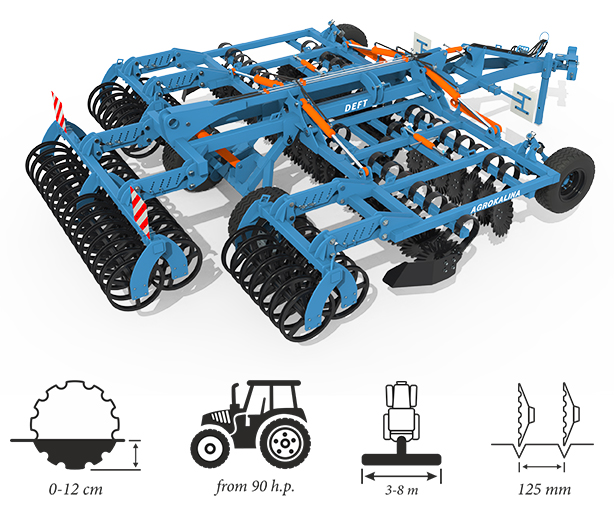

Cultivator will quickly and qualitatively prepare the soil for sowing on the plowed field. One pass of the unit ensures perfectly prepared soil for sowing.

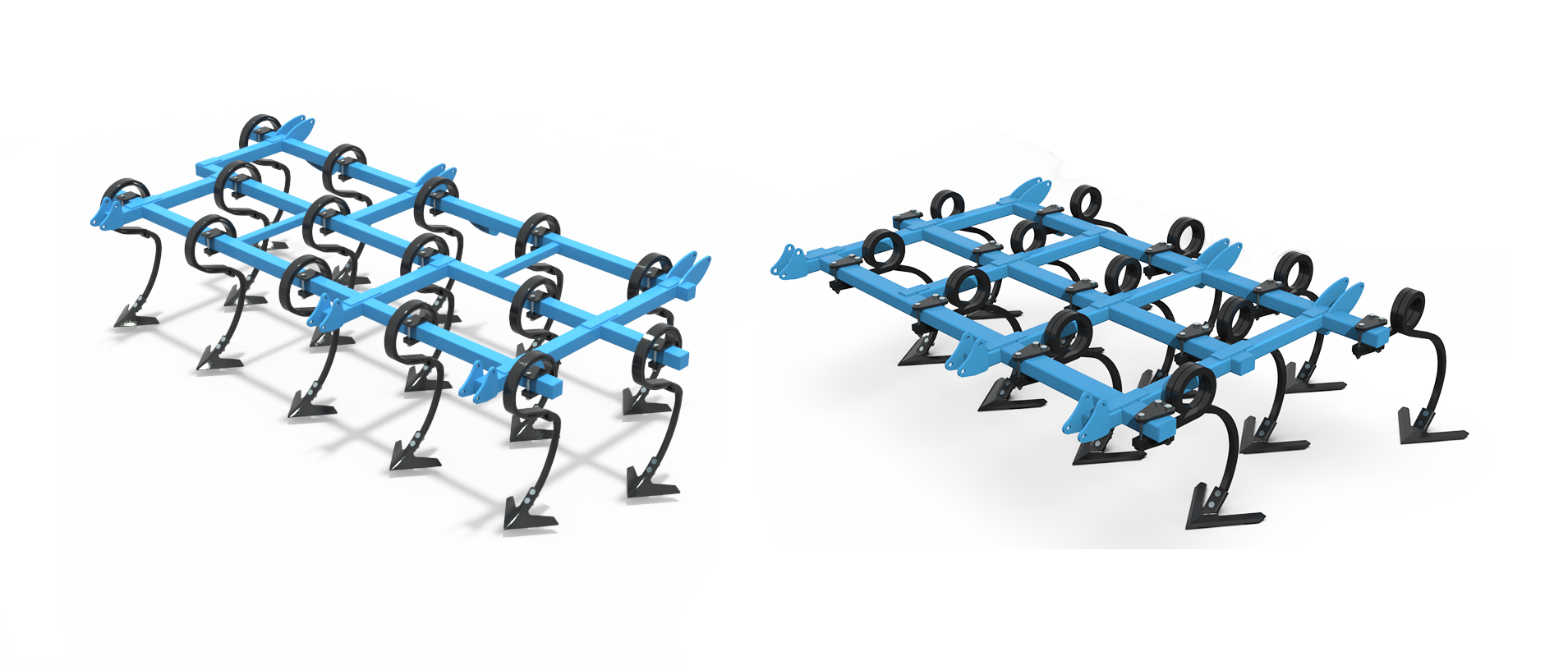

- The seedbed and the leveled, finely lumpy seed layer of the soil are created thanks to the optimal combination of arrow paws, slatted and ring-spur rollers in the machine.

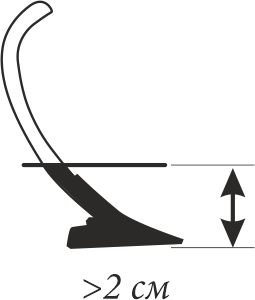

- The depth of processing is regulated by changing the position of the arrow paws relative to the front slatted and rear ring-spur rollers.

- The multi-row installation of arrow legs on the frame of the cultivator ensures the exact depth of soil cultivation and prevents clogging of the working organs.

- The use of a cultivator contributes to the friendly appearance of seedlings of agricultural crops.

- Gripping width - depending on the configuration, from 3 to 9 meters.

- Minimal labor costs when servicing the machine. Ensuring maximum safety for personnel.

- It is aggregated with tractors with traction force from 90 to 340 horsepower.

- It is transferred to the transport position by the hydraulic system installed on the cultivator.

- The width in the transport position for a machine with a working width of up to 6 meters — 3 meters, up to 9 meters — 4,5 meters.

Key features

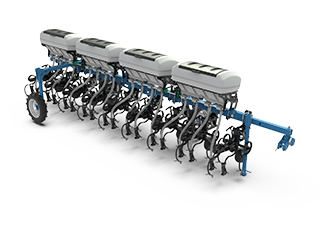

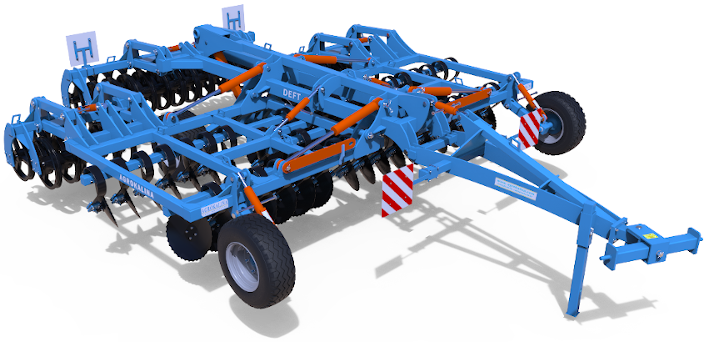

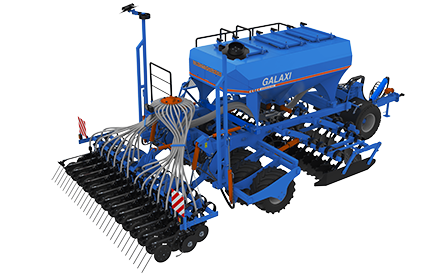

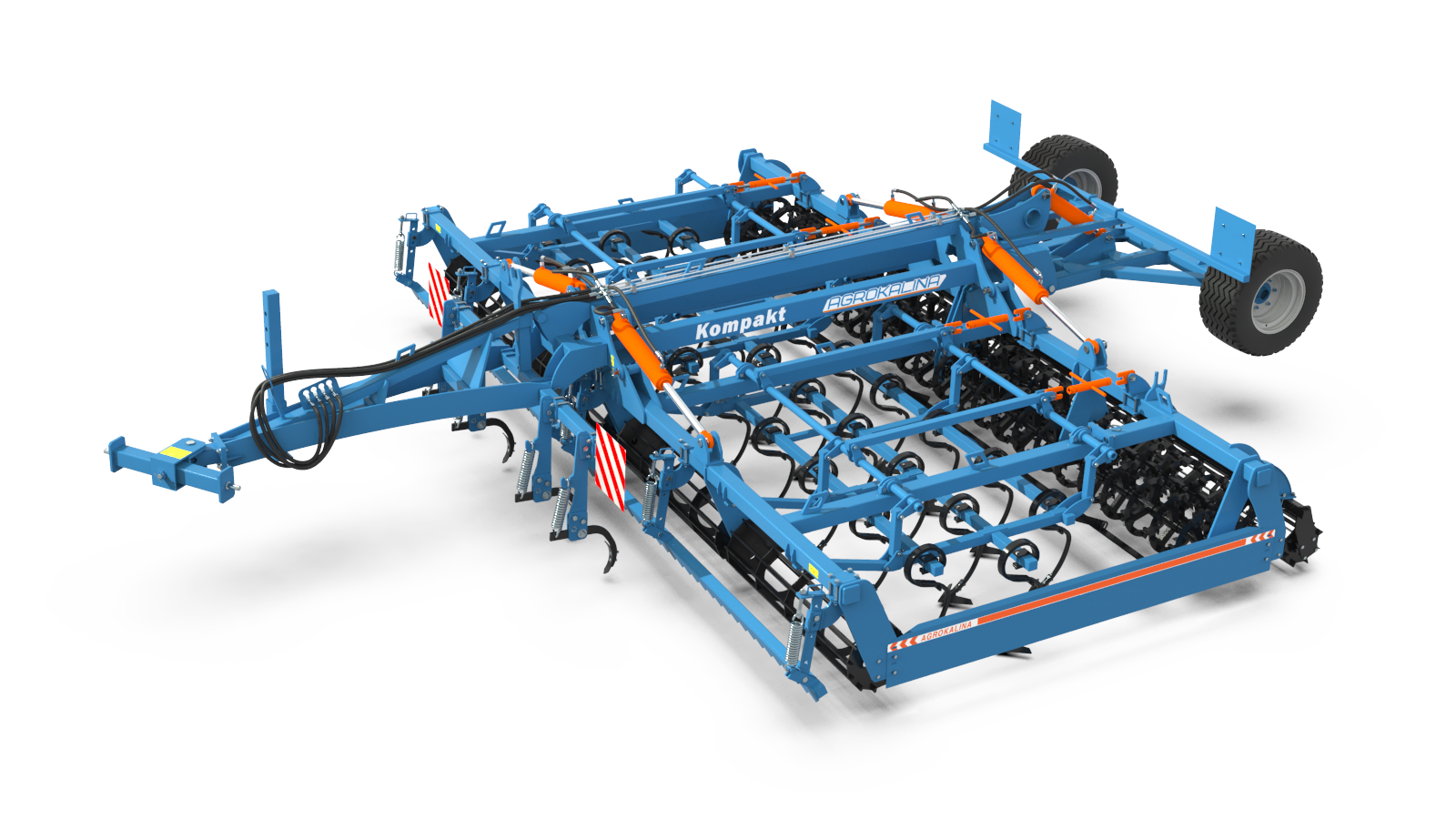

UP TO 7 WORKING OPERATIONS IN ONE PASS

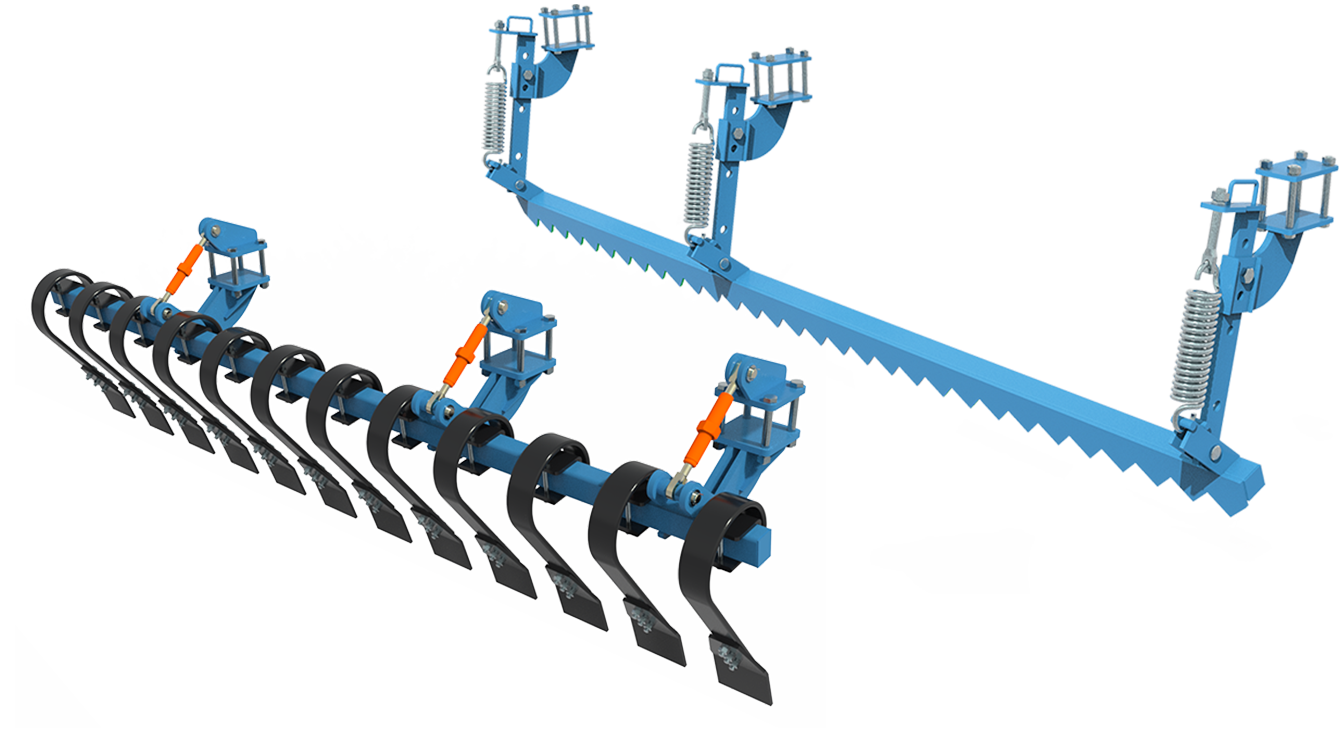

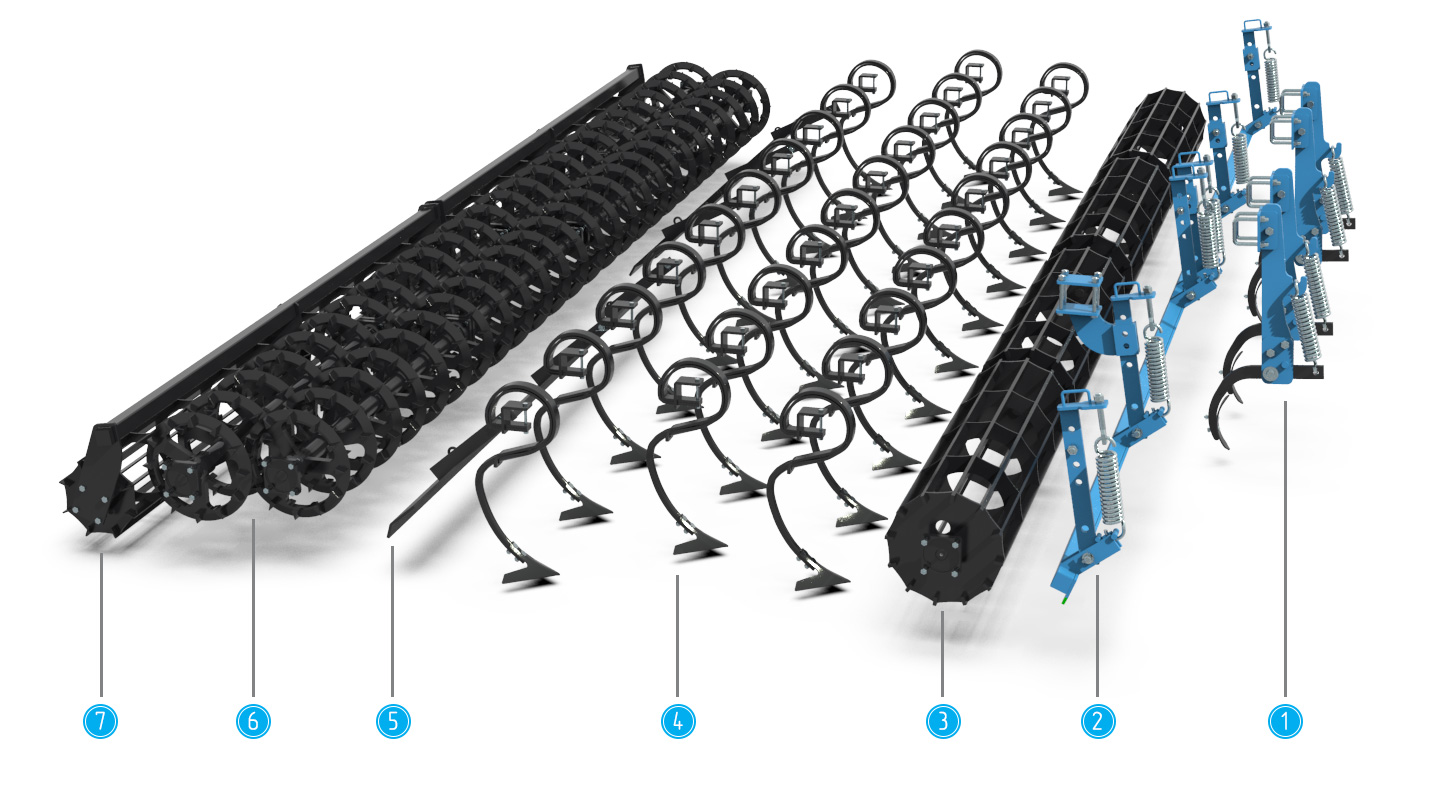

Combining multiple operations in one pass means fewer passes across the field, which reduces soil compaction, moisture retention, and reduced soil preparation costs. The front bar perfectly evens out any irregularities in the field. The front slatted roller grinds lumps. The main working section prepares the seed bed after plowing in one pass, while the soil is enriched with oxygen, this contributes to better warming of the soil. The final crushing of lumps is provided by different types of rear rollers in possible combination with other additional equipment behind them.

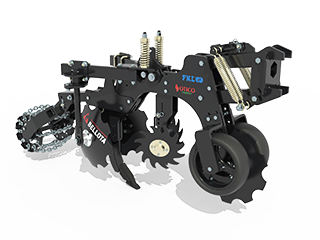

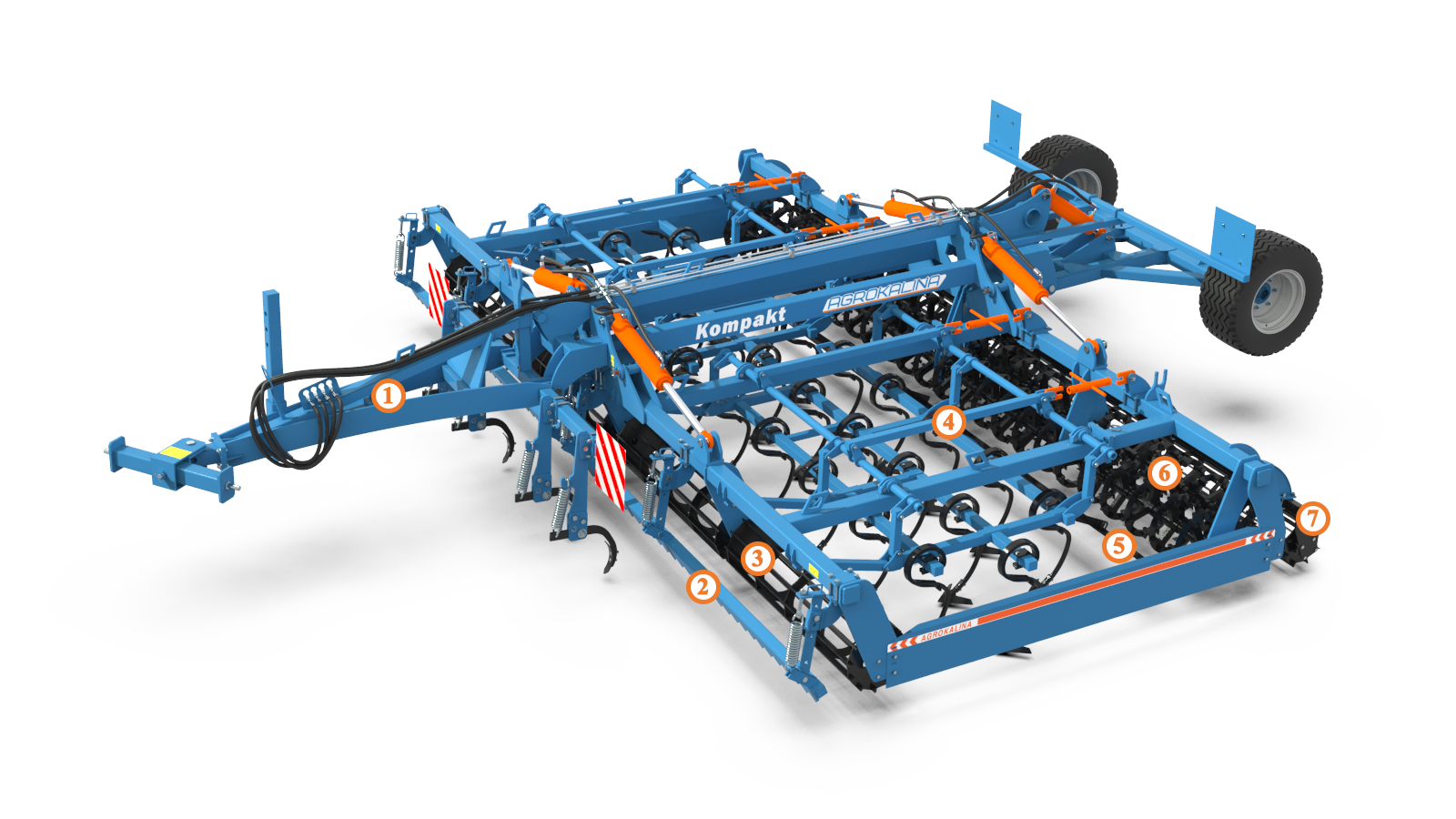

1. Tractor wheel track loosener for softening compacted soil.

2. Plate of the front pile for preliminary leveling of the surface.

3. Front roller for primary grinding of lumps.

4. The working section cuts and levels the soil.

5. The plate of the middle harrow levels the loosened soil and further directs its kind to the rear roller.

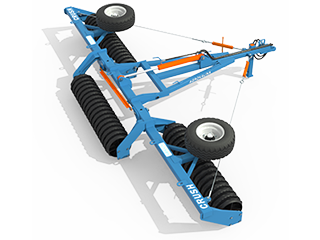

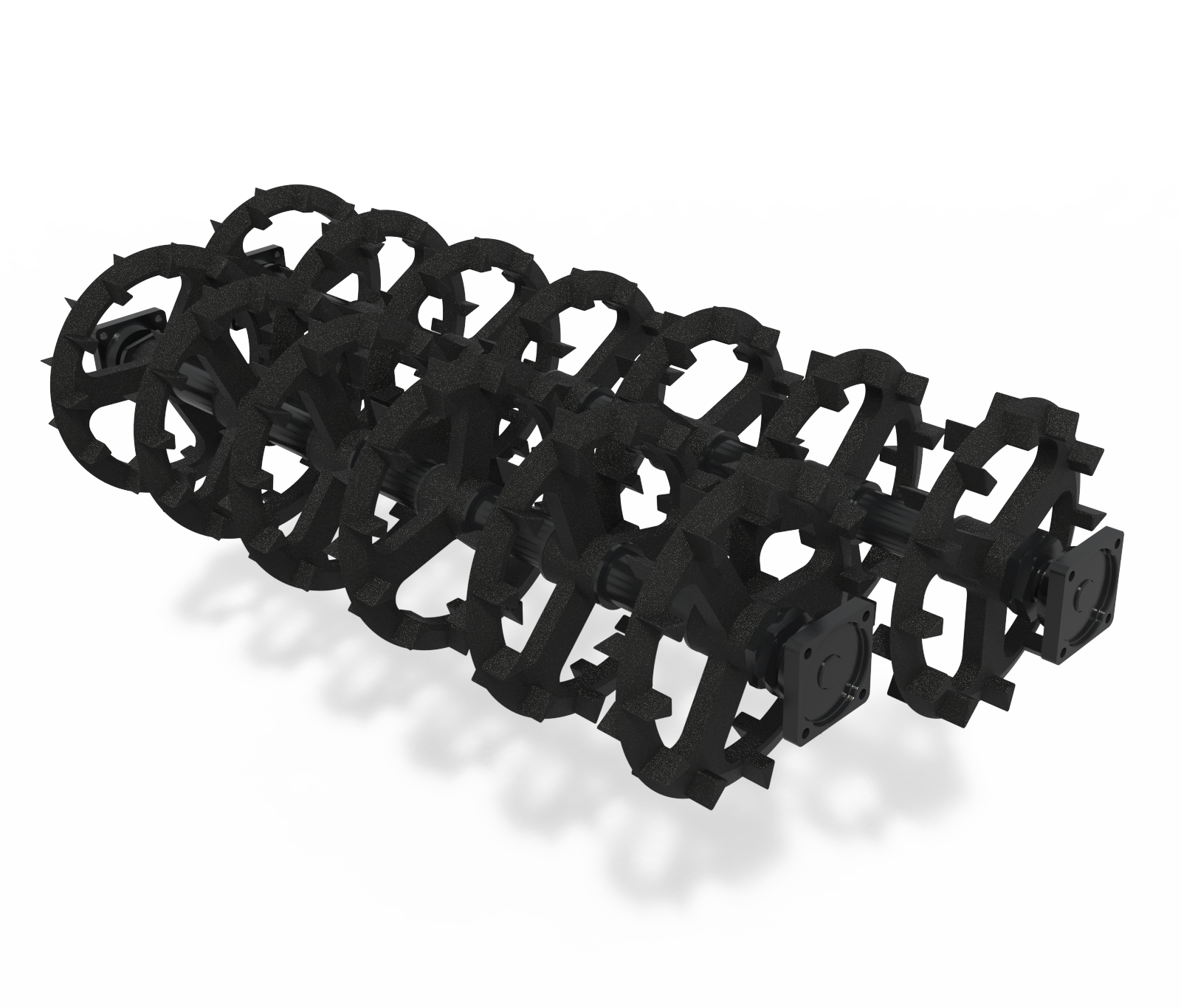

6. The double Crosskill roller is an ideal solution for all types of soil. High-quality cast-iron rollers perfectly grind the soil and have a self-cleaning effect.

7. The rear finishing roller provides intensive grinding thanks to the high angular speed.

THE MOST AVAILABLE UNIT

PROVEN DESIGN

Do not waste time, turn around the edge of the field without lifting the unit.

Thanks to its design, the AKPK compactor provides a smooth turn at the edge of the field without the need to completely clear the working sections. Nevertheless, we recommend turning with a slightly shallower working section and a large turning radius.

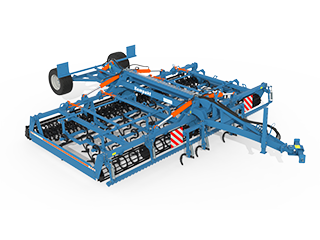

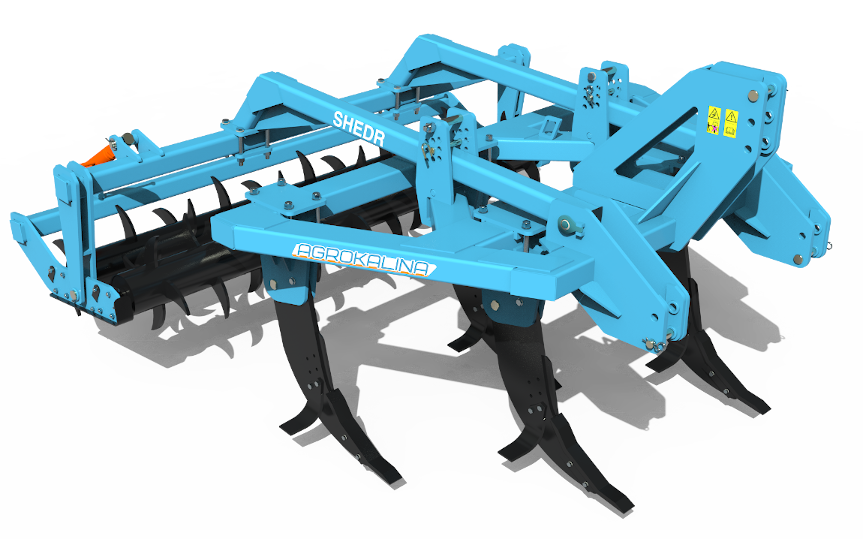

VOLUME FRAME

The even distribution of weight ensures a higher durability of the unit.

Side frames with separate working sections are attached to a strong central supporting frame. It has higher strength because the weight of the side frames is evenly distributed. To ensure safe transportation, the unit is equipped with an integrated transport axle.

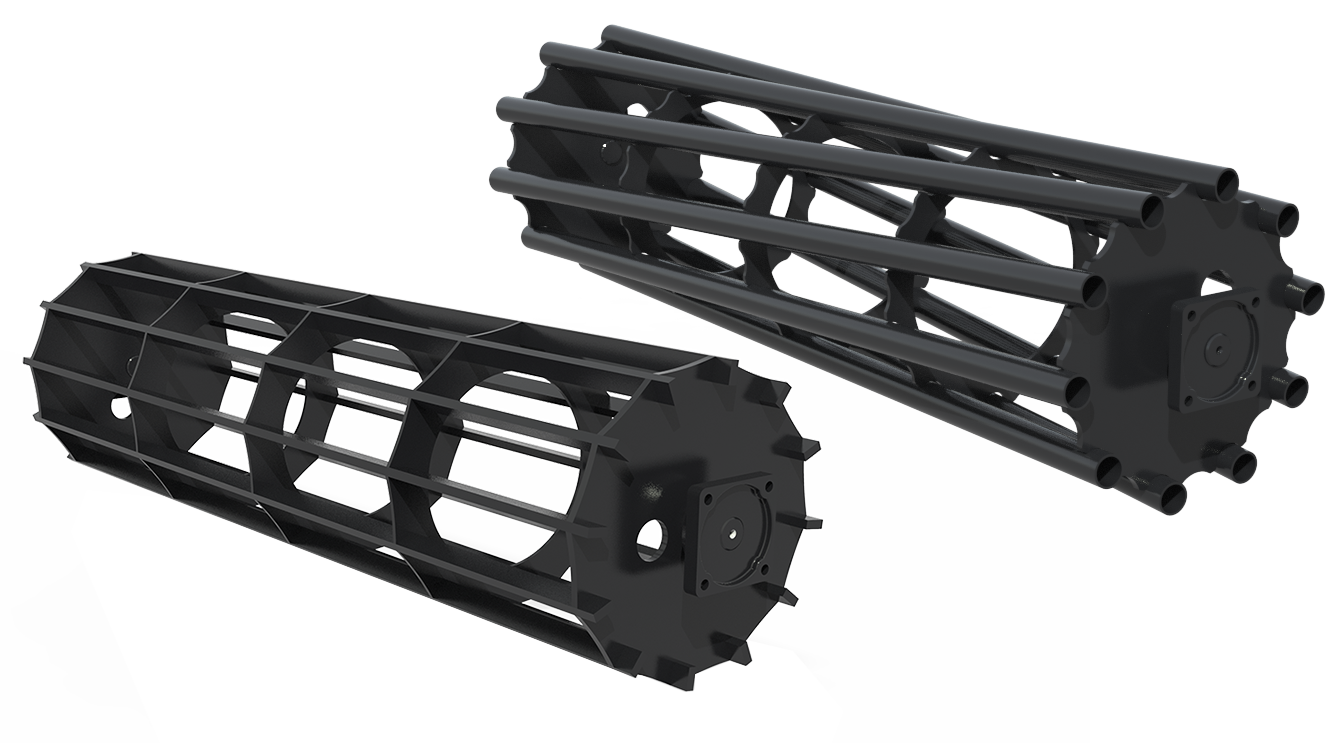

Bearing unit

Bearing unit LSFR 308 is a new generation of units with radial thrust bearings. Developed by specialists, especially for heavy rollers of disc harrows working in difficult soil processing conditions. Structurally, the unit consists of a self-aligning radial-thrust ball bearing that is fixed, with a unique system of protective seals of increased reliability and a molded FR 308 housing, which exceeds standard housings in terms of strength by four times.

Developed to order from manufacturers of agricultural machinery, it has undeniable competitive advantages:

- Greater exploitation resource;

- Improved protection against the action of earth, dust, water, moisture, steam;

- Does not require additional protection against impacts from solid objects;

- The minimum amount of backlash allows to guarantee the stability of the technical parameters of agricultural units;

- Ability to provide high bending stiffness and compression stability of the disk battery pack.

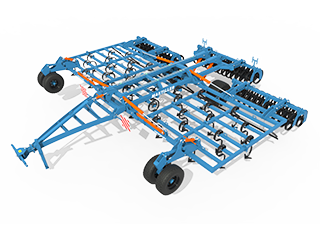

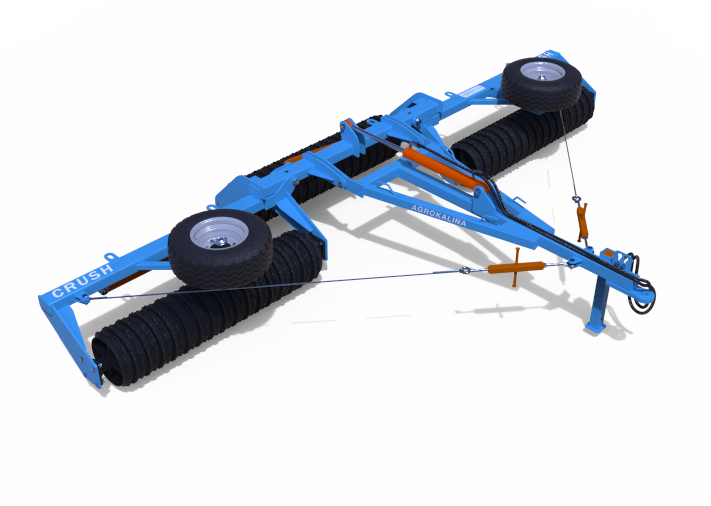

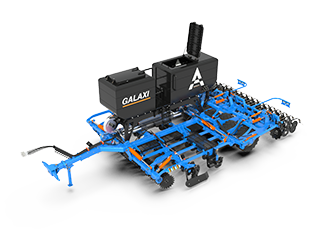

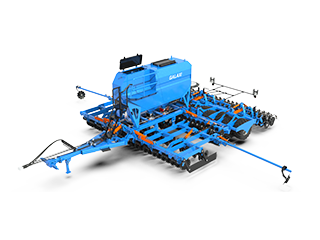

3D overview of the unit

![]()

CONCEPT

AKPK compactors — Model range

Configuration options

Specifications

| Parameter name | AKPK-3 | AKPK-4 | AKPK-5 | AKPK-6 | AKPK-8 | AKPK-9 |

|---|---|---|---|---|---|---|

| 1. Productivity, ha/h | 2,4-3,6 | 3,2-4,8 | 4,0-6,0 | 4,8-7,2 | 6,4-9,6 | 7,2-10,8 |

| 2. Working speed, km/h | 8-12 | 8-12 | 8-12 | 8-12 | 8-12 | 8-12 |

| 3. Width of capture, mm | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 9,0 |

| 4. Processing depth, mm | 40-120 | 40-120 | 40-120 | 40-120 | 40-120 | 40-120 |

| 5. Number of working bodies, pcs | 15 | 20 | 24 | 30 | 39 | 45 |

| 6. Distance between paws, mm | 200 | 200 | 200 | 200 | 200 | 200 |

| 7. Overall dimensions | ||||||

| - in working position, to | ||||||

| length, mm | 7000 | 7700 | 7700 | 7700 | 7700 | 7700 |

| width, mm | 3100 | 4100 | 5000 | 6000 | 8200 | 9200 |

| height, mm | 1400 | 1600 | 1960 | 1960 | 1400 | 1400 |

| - in transport position, to | ||||||

| length, mm | 6800 | 7500 | 7500 | 7500 | 7500 | 7500 |

| width, mm | 3100 | 4100 | 3100 | 3100 | 4500 | 4500 |

| height, mm | 1500 | 1700 | 3600 | 4100 | 4000 | 4500 |

| 8. Width of paws, mm | 260 | 260 | 260 | 260 | 260 | 260 |

| 9. Height to the frame of attachment of working bodies, mm | 500 | 500 | 500 | 500 | 500 | 500 |

| 10. Width between rows of paws, mm | 500 | 500 | 500 | 500 | 500 | 500 |

| 11. Overlap of working bodies, mm | 60 | 60 | 60 | 60 | 60 | 60 |

| 12. Distance between paws in one row, mm | 600 | 600 | 600 | 600 | 600 | 600 |

| 13. Weight of the structure, kg | 2500 | 3500 | 4400 | 5300 | 7000 | 7500 |

| 14. Aggregated with tractors, k. p. | 90-110 | 110-150 | 150-180 | 180-240 | 240-310 | 310-340 |

Do you have questions about the operation of the unit?

Our managers will gladly help you! Call or write to us!